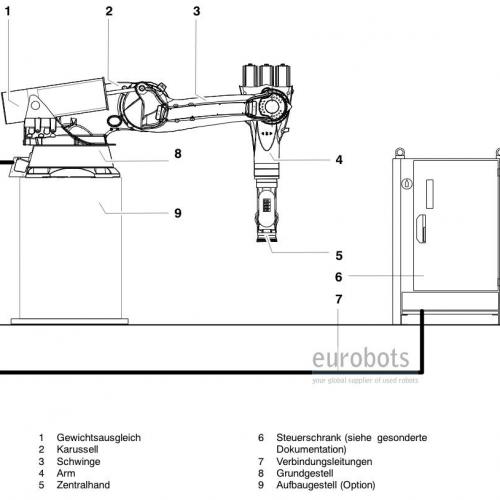

6 axis industrial robot, shelf version of the KR150 KR180 KR210 series 2000. This shelf-mounted robot can be integrated into a machine with the role of a "top loader" and can thus carry out loading and unloading as well as complex finishing of the parts produced in the machine – all in a single operation.

Equipped with the KRC2 control cabinet.

The KR C2 robot controller makes programming easier with its Microsoft Windows interface. It is expandable, can be integrated into networks via a bus, and contains ready-made software packages.

KR C2 features:

* Open, network-capable PC technology

* 2 free slots for external axes

* DeviceNet and Ethernet slots for common bus systems (e.g. INTERBUS, PROFIBUS, DeviceNet) provided as standard

* Motion profile function for optimal interaction between the individual robot motors and their velocity

* Floppy disk and CD-ROM drives for data backup

* Facilities such as remote diagnosis via the Internet

* Simple operation and programming via KUKA Control Panel (KCP) with Windows user interface

* Compact control cabinet

* Ergonomic KUKA Control Panel (KCP)

Robot Info

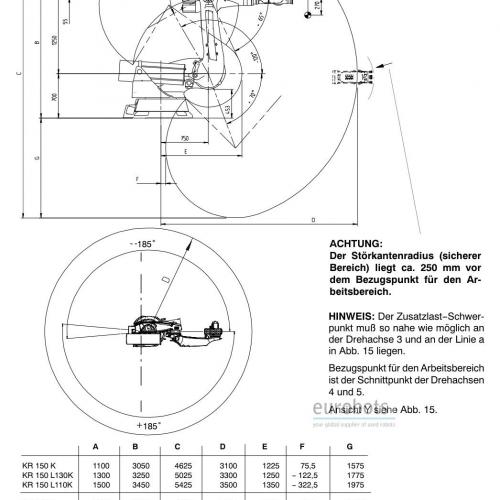

- Maximum Load of Robot: 210/150 Kg

- Maximum Reach: 3100/3500 mm

- Repeatability: 0,1 mm

- Controller: KRC2

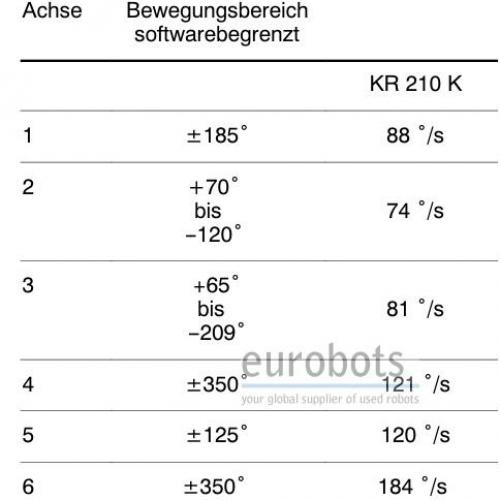

Robot Motion Speed

- Axis 1: 88º/s

- Axis 2: 74º/s

- Axis 3: 81º/s

- Axis 4: 121º/s

- Axis 5: 120º/s

- Axis 6: 184º/s

Robot applications

- Press tending

- Machine tending

- Loading and unloading

- Coating and bonding

- Handling

- Assembly

- Palletizing and order picking

- Spotwelding

- Glueing

- Machining

Applications

Spotwelding , Press tending , Palletising , Loading and unloading of parts , Machining , Handling of parts , Assembly of parts , Glueing - Adhesive bonding

Pictures

Videos

Diagrams