The industrial robot KR 360 R2830 has a dynamic design ideal for handling heavy loads; With a load capacity of 360 kg and an arm reach of 2,826 mm. It is characterized by its high repeatability and maximum reach as it is a cost-effective solution for heavy load industries, has different variants for working environments resistant to heat, dust and water, position in floor mounting, IP65 protection.

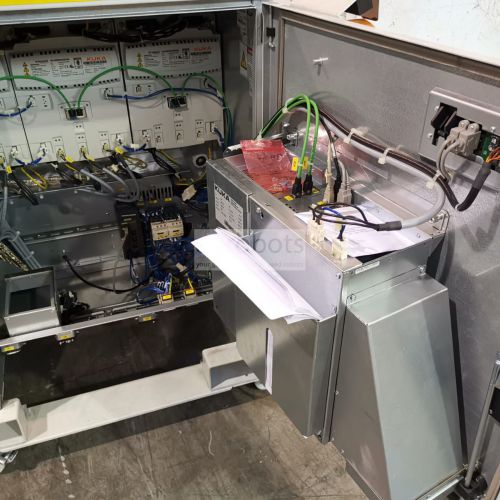

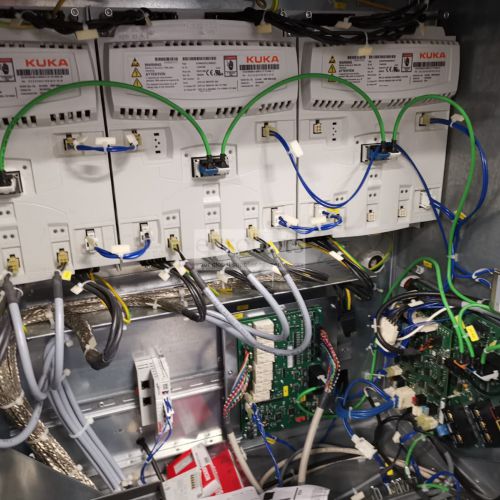

KR C4 - Newest Kuka controller

| VARIANTS | KR 360 R2830 | KR 360 R2830 C | KR 360 R2830 F | KR 360 R2830 C-F |

| Maximum load of robot: | 360 Kg | 360 Kg | 360 Kg | 360 Kg |

| Number of axis: | 6 | 6 | 6 | 6 |

| Maximum horizontal reach: | 2,826 mm | 2,826 mm | 2,826 mm | 2,826 mm |

| Repeatability: | ±0,08 mm | ±0,08 mm | ±0,08 mm | ±0,08 mm |

| Controller: | KR C4 | KR C4 | KR C4 | KR C4 |

| Mounting position | Floor | Ceiling | Floor | Ceiling |

| VARIANTS | KR 360 R2830 | KR 360 R2830 C | KR 360 R2830 F | KR 360 R2830 C-F |

| Axis 1 | ±185° | ±185° | ±185° | ±185° |

| Axis 2: | -130°/ 20° | -130°/ 20° | -130°/ 20° | -130°/ - 20° |

| Axis 3: | -100°/144° | -100°/144° | 100°/144° | -100°/144° |

| Axis 4: | ±350° | ±350° | ±350° | ±350° |

| Axis 5: | ±120° | ±120° | ±120° | ±120° |

| Axis 6: | ±350° | ±350° | ±350° | ±350° |

Axis 2: 90°/s

Axis 3: 90°/s

Axis 4: 120°/s

Axis 5: 110°/s

Axis 6: 160°/s

Testing and inspection

Metal die-casting machines

Foundry works

Handling for other machines

Palletizing

Cutting machine tools

Packaging and order picking

Laser welding

Spot welding

Machining

Fastening

Inserting, mounting

assembly/disassembly operations

Laser cutting

Waterjet cutting

Forging plants

Applications

Arc welding , Spotwelding , Palletising , Loading and unloading of parts , Machining , Handling of parts , Measurement , Assembly of parts , Laser cutting , Laser welding Nd-Yag , Stud welding , Plasma cutting

Pictures

Videos

Diagrams