KUKA KR150K

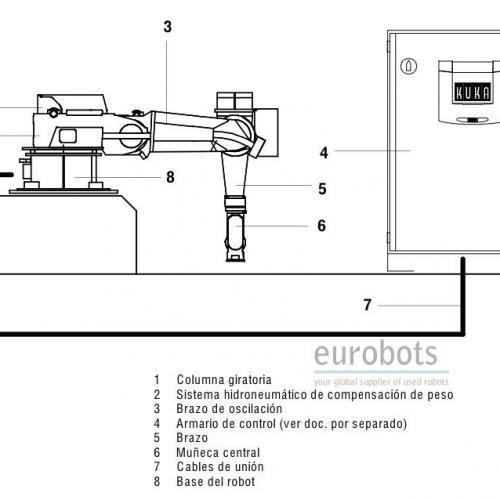

Year 1999-2000. Quite robust and reliable machine. The KUKA KR150K/1 KUKA shelf-mounted robots can be integrated into a machine in the role of a "top loader" and can thus carry out loading and unloading as well as complex finishing of the parts produced in the machine – all in a single operation. Equipped with the KRC1 control cabinet, 4.1.4 version.

KR C1 controller specifications:

- Open PC technology with networking capability.

- CAN/DeviceNet and Ethernet as standard. Slots for common bus systems (e.g. INTERBUS-S,FIPIO).

- Integrated oscilloscope function for robot diagnosis and programming support.

- Motion profile function for optimum interaction between the individual robot motors and their velocity.

- Floppy disk and CD-ROM drives for backing up data.

- Facilities such as master/slave operation of robots or remote diagnosis via the Internet.

- Easy operator control and programming via KUKA Control Panel (KCP) with Windows 95

- graphic user interface.

- Compact, stackable control cabinet.

- One controller for all robot models.

- Ergonomic KCP design.

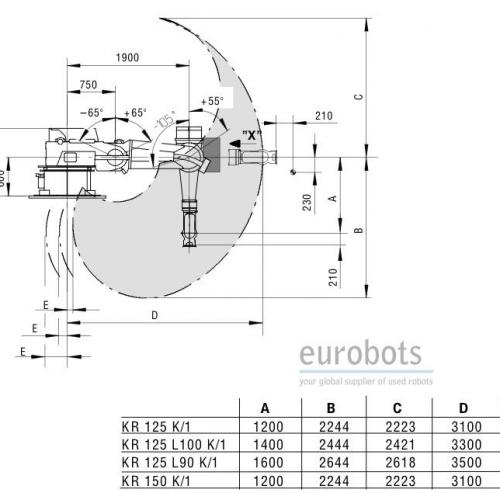

Robot Info:

- Maximum Load of Robot: 150 Kg.

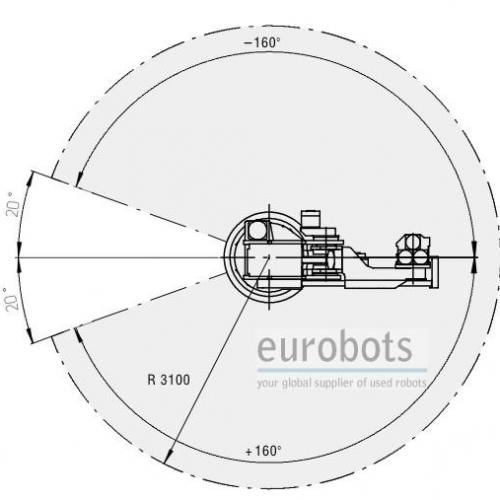

- Maximum Reach: 3100 mm.

- Repeatability: 0,2 mm.

- Controller: KR C1.

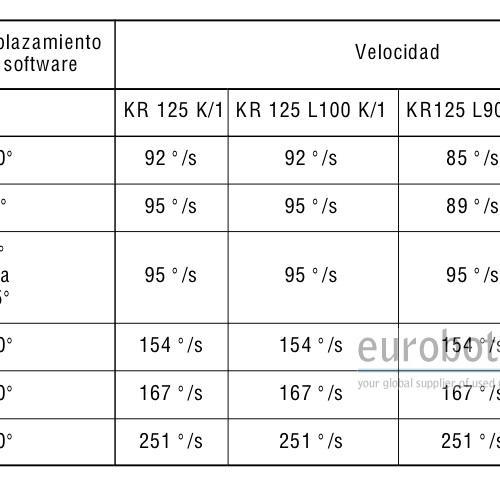

Robot Motion Speed:

- Axe 1: 76º/s

- Axe 2: 76º/s

- Axe 3: 80º/s

- Axe 4: 129º/s

- Axe 5: 128º/s

- Axe 6: 176º/s

Robot Applications:

- Machining

- Machine tending

- Polishing, grinding and deburring

- Coating and bonding

- Handling

- Measuring and testing

- Assembly

- Palletizing and order picking

- Cutting

- Welding

Applications

Spotwelding , Press tending , Palletising , Loading and unloading of parts , Machining , Handling of parts , Glueing - Adhesive bonding

Pictures

Videos

Diagrams

English

English

Spain

Spain

Germany

Germany

France

France

Russia

Russia

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

India

India

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru