KUKA KR6/2

/// The KR 6 is typically used in arc welding applications, a masterful mover with a fist-shaped work envelope, and is ideal for the implementation of cost-effective, space-saving system concepts.

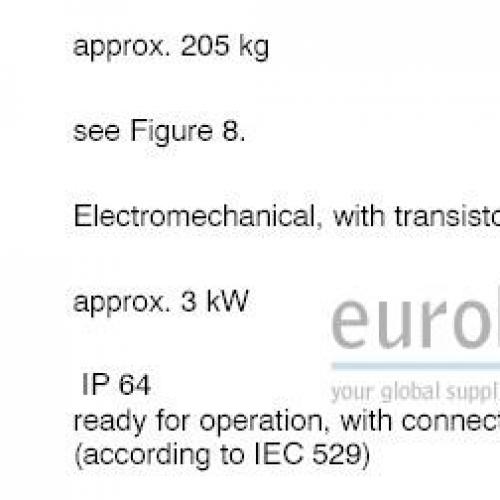

Equipped with the Windows 95 based KR C1 controller.

KR C1 controller specifications:

• Open PC technology with networking capability.

• CAN/DeviceNet and Ethernet as standard. Slots for common bus systems (e.g. INTERBUS-S,

FIPIO).

• Integrated oscilloscope function for robot diagnosis and programming support.

• Motion profile function for optimum interaction between the individual robot motors and their

velocity.

• Floppy disk and CD-ROM drives for backing up data.

• Facilities such as master/slave operation of robots or remote diagnosis via the Internet.

• Easy operator control and programming via KUKA Control Panel (KCP) with Windows 95

graphic user interface.

• Compact, stackable control cabinet.

• One controller for all robot models.

• Ergonomic KCP design.

Robot Info:

- Maximum Load of Robot: 6 Kg.

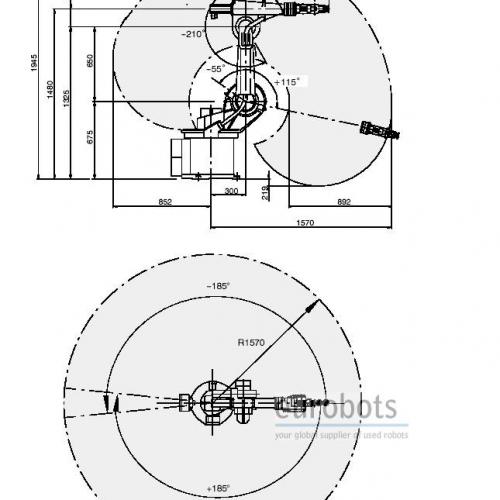

- Maximum Reach: 1500 mm.

- Repeatability: 0,1 mm.

- Controller: KR C1

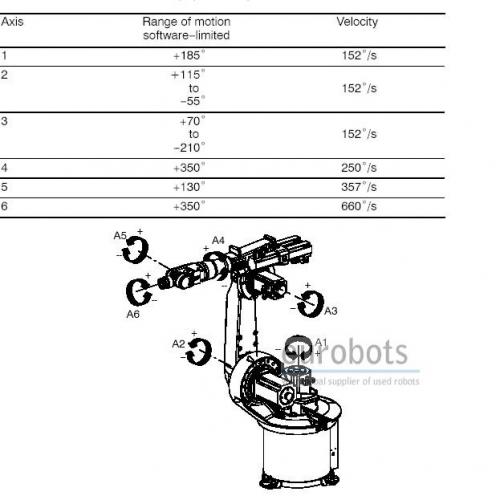

Robot Motion Speed:

- Axe 1: 152º/seg

- Axe 2: 152º/seg

- Axe 3: 152º/seg

- Axe 4: 250º/seg

- Axe 5: 357º/seg

- Axe 6: 660º/seg

Robot Applications:

- Arc welding

- Machining

- Machine tending

- Polishing, grinding and deburring

- Coating and bonding

- Handling

- Measuring and testing

- Assembly

- Palletizing and order picking

- Cutting

Applications

Arc welding , Painting , Loading and unloading of parts , Handling of parts

Pictures

Videos

Diagrams

English

English

Spain

Spain

Germany

Germany

France

France

Russia

Russia

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

India

India

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru